Ultimate Guide to Selecting Scissor Lifts for 2026 Projects

As construction and maintenance projects evolve, selecting the right equipment becomes increasingly critical. In 2026, scissor lifts have become indispensable tools for various tasks across multiple industries. These versatile machines provide the elevation needed for tasks ranging from electrical installations to ceiling maintenance. However, choosing the right scissor lift requires careful consideration of several factors to ensure optimal performance and safety.

Understanding Scissor Lifts

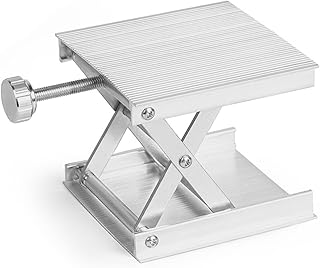

Scissor lifts are characterised by their crisscrossing support arms that extend vertically, allowing for a safe working platform at height. They come in various sizes and types, catering to different project requirements. Understanding the specific needs of your project is essential in selecting the appropriate scissor lift. The primary types include electric, diesel, and hybrid models, each with its own advantages and limitations.

Key Factors to Consider

When selecting a scissor lift for your 2026 projects, consider the following key factors:

1. Load Capacity

One of the most critical factors in selecting a scissor lift is its load capacity. Depending on the tasks you plan to perform, you will need to assess the weight of the personnel and equipment that the lift must support. Most scissor lifts have a load capacity ranging from 227 to 1,134 kilograms. It is vital to choose a lift with a capacity that comfortably exceeds your maximum expected load to ensure safety and stability.

People Also Look For:

- Motorcycle Jack Stands Low Profile 0.5 Ton 11000Lbs Capacity Steel Motorbike Bike Lifting Stand Height Adjustable Jack Stand for S...

- SuperHandy Hardware Lift Winch Stacker, Pallet Truck Cart, Lift Table, Fork Lift, Max Lift 150kg, 40" with 8" Wheels, Swivel Caste...

- VIVOHOME Motorcycle Lift Jack Stand 158KG Heavy Duty Hydraulic Operated ATV Dirt Bike Scissor Stand with 4 Wheels

- Adjustable Lab Lift Stand Stainless Steel Lift Table Lab Stand Scientific Lab Lift Platform Stands Rack Scissor Lab Lifter for Sci...

- Labsales Heavy Duty Lab Jack stand, Stainless Steel Scissor Lift for laboratory Instruments & Reagent Bottles, Low Profile, Adjust...

2. Platform Height

The maximum platform height is another vital consideration. Scissor lifts typically offer working heights ranging from 6 to 18 metres. Choosing a lift that meets your specific height requirements will ensure that your team can safely reach the necessary work areas without overextending or compromising safety. Always account for any additional height needed for equipment or tools being used.

3. Terrain and Environment

The terrain on which the scissor lift will operate significantly influences your choice. If your projects will be conducted on rough or uneven ground, a diesel-powered scissor lift with robust wheels may be more suitable. In contrast, electric lifts are ideal for indoor use on smooth surfaces. Additionally, consider the environment, such as exposure to moisture or chemicals, which may impact the lift's functionality and durability.

4. Power Source

Scissor lifts are available in electric and diesel variants, and your choice should align with your project requirements. Electric scissor lifts are quieter and more environmentally friendly, making them ideal for indoor use. Diesel models, however, offer more power and are better suited for outdoor applications or rugged terrains. Consider the power source that aligns best with your project needs and operational environment.

5. Safety Features

Safety should always be a top priority when selecting a scissor lift. Look for models equipped with essential safety features such as guardrails, emergency stop buttons, and automatic braking systems. Additionally, it is advisable to select a lift with a stability control system to prevent tipping, especially when working at height. Ensure that the lift complies with all relevant safety regulations and standards.

6. Maintenance and Support

Before making a purchase, consider the maintenance requirements and support offered by the manufacturer or rental company. Regular maintenance is essential for the longevity and safety of the scissor lift. It is advisable to choose a supplier with a solid reputation for customer support and quick service response times. Understanding the maintenance schedule and potential costs can help you manage your project budget effectively.

7. Rental Versus Purchase

Deciding whether to rent or purchase a scissor lift can significantly impact your project costs. If your project is a one-off or short-term, renting may be the most economical option. However, if you anticipate ongoing use, purchasing could provide long-term savings. Consider your project timeline and frequency of use when making this decision.

By carefully evaluating these factors, you can select a scissor lift that meets your specific project requirements. The right choice will enhance productivity while ensuring the safety of your team and the success of your projects in 2026.